The blog is written following an interview with Dr. Ramdev Yash Pal, UNIDO Technical Advisor for the project.

NIP Dialogue Series – Voices from the Countries

India, the world’s only remaining manufacturer of Dichloro-Diphenyl-Trichloroethane (DDT), is demonstrating what a managed, strategic transition away from Persistent Organic Pollutants (POPs) can look like. Hindustan Insecticides Limited (HIL), as the sole global manufacturer, plays a pivotal role in this journey. While the use of DDT for Indoor Residual Spraying (IRS) remains permitted under World Health Organization (WHO) guidelines, India, as a signatory to the Stockholm Convention (SC), is actively working toward a consistent phase-out. This shift is supported by a GEF-funded project (ID 4612 titled as “Development and Promotion of Non-POPs Alternatives to DDT” implemented by the United Nations Industrial Development Organization (UNIDO) as the leading agency and by the United Nations Environment Programme (UNEP), which has showcased how safer, more sustainable alternatives can meet public health needs while protecting the environment and advancing socio-economic development. The project promotes solutions for managing disease vectors, particularly mosquitoes that spread malaria, offering lessons for countries navigating similar transitions.

To guide this transition, India is combining innovation, regulation, and collaboration. Each component plays a vital role in reducing reliance on harmful chemicals while ensuring effective vector control.

Integrated alternatives to DDT

India's transition strategy is built on a combination of chemical and non-chemical interventions that address multiple mosquito life stages:

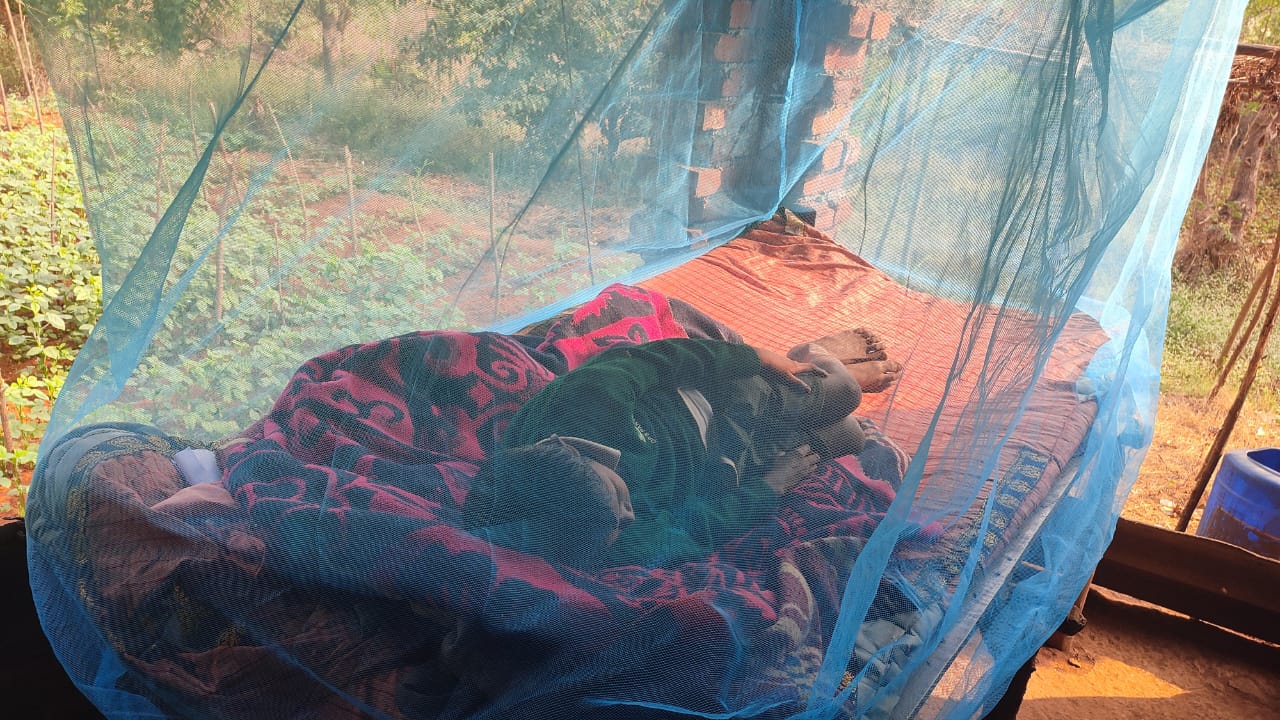

- Long-Lasting Insecticidal Nets (LLINs): Produced at HIL's Rasayani facility in Maharashtra using technology transferred by the Central Institute of Petrochemicals Engineering and Technology (CIPET). Production began in 2020 with a capacity of 5 million nets per year and expanded to 10 million nets in 2024 to meet rising national demand.

- Bacillus thuringiensis israelensis (Bti)-based Biolarvicides: These microbial agents specifically target mosquito larvae and are being developed for large-scale manufacturing at HIL’s Rasayani site, using technology transferred from the Indian Council of Medical Research - Vector Control Research Centre (ICMR-VCRC).

- Neem-Based Botanical Products: These include neem-based larvicides (such as suspension concentrates, spreading oils, and floating tablets) and repellents (creams and coils). Development and formulation were supported by the Institute of Pesticide Formulation Technology (IPFT).

Together, these alternatives provide a comprehensive, stage-specific approach to vector control that is more effective and sustainable than DDT.

|

|

Legislative and institutional support

On the regulatory front, the Government of India has taken several strong supportive measures to facilitate the transition:

- Prioritized registration: The Central Insecticides Board (CIB) has prioritized the registration process for non-POP alternatives.

- Expert review and approval: The registration application undergoes a comprehensive review by subject matter experts before being presented to the Registration Committee for final approval, ensuring that only safe and effective alternatives are permitted for use.

- Policy integration: Alternatives have been incorporated into the Ministry of Health and Family Welfare’s Vector-Borne Disease Control Programme.

- Guidance to states: State Health Departments have been advised to promote the adoption of these alternatives through government circulars and programmatic guidance.

This approach through policy and regulatory framework ensures that alternatives to DDT are not only developed and manufactured but also systematically integrated and mainstreamed into national and sub-national public health strategies.

Engaging communities and empowering women

Community involvement has been central to the project’s success. More than 200 women have been employed in the LLIN production facility, offering livelihood opportunities and contributing to women's empowerment in rural areas. Awareness campaigns and stakeholder training sessions have helped communities and health workers understand the benefits and application of non-POP vector control tools.

|

|

Public-private partnerships (PPPs) and institutional collaboration

This project has thrived on the foundation of strong collaboration between public institutions and private actors, illustrating how coordinated efforts across sectors can accelerate the transition to safer alternatives. Research and development institutions such as the Central Institute of Petrochemicals Engineering and Technology (CIPET), the Indian Council of Medical Research - Vector Control Research Centre (ICMR-VCRC), and the Institute of Pesticide Formulation Technology (IPFT) played an important role by providing the core technologies and supporting the development of new products. These innovations were brought to life at HIL’s Rasayani facility, which has become the central hub for the production of Long-Lasting Insecticidal Nets (LLINs) and biolarvicides. To ensure these products reach the communities that need them most, the Ministry of Health and Family Welfare has taken responsibility for nationwide distribution, while NGOs, public sector undertakings (PSUs), municipal bodies, and defense organizations have contributed to their widespread dissemination and adoption. In parallel, private sector entities have supported the development of detailed project reports (DPRs) and market assessments through the Public-Private Partnership (PPP) model. Adding to its technical and manufacturing contributions, HIL has also taken on an advocacy role by actively participating in national and international conferences and vector control forums to share lessons learned and promote the uptake of non-POP alternatives. These events have become key platforms for raising awareness, facilitating knowledge exchange, and engaging in policy dialogue—demonstrating the comprehensive and collaborative nature of India’s strategy to move beyond DDT.

Cost effectiveness: A long-term investment

Although the initial application cost of DDT is lower, the alternatives introduced through the GEF-UNIDO project have proven to be more cost-effective in the long term. For example, LLINs provide up to three years of protection with minimal maintenance, reducing the need for repeated applications and associated logistical costs. In contrast, DDT requires frequent reapplication, adding to long-term expenses. Moreover, non-POP alternatives pose significantly fewer environmental and health risks, supporting sustainability and resilience in national vector control strategies.

Lessons for other countries: A replicable model

India’s experience offers a practical and adaptable model for other countries aiming to move away from DDT. A key takeaway is the importance of developing indigenous, cost-effective technologies that are suited to the local ecological and economic context. Establishing local manufacturing units not only reduces dependency on imports but also stimulates employment and economic growth. Simplifying regulatory processes ensures faster approval and accessibility of non-POP alternatives. An especially important aspect of India’s transition is the active involvement of Hindustan Insecticides Limited (HIL)—the country’s main DDT producer—not as an obstacle, but as a key partner. Instead of resisting change, HIL collaborated with government agencies and development partners to shift toward producing and distributing safer alternatives, demonstrating that meaningful progress can be achieved through cooperation rather than confrontation. The success of this initiative also lies in the strong collaboration between public institutions and private partners through Public-Private Partnerships (PPPs), which facilitated technology development and product rollout. Community engagement, particularly training local health workers and empowering women in production roles, further ensured the sustainability and inclusivity of the transition. Finally, proactive awareness-raising and outreach built confidence in these alternatives among policymakers, health authorities, and the public, paving the way for broader adoption.

"These alternatives provide effective and long-lasting protection while aligning with our environmental and health priorities," said Dr. Ramdev Yash Pal, UNIDO Technical Advisor for the project. "India’s experience shows that with the right partnerships and policy support, phasing out DDT is not only achievable—it’s the better choice."

A path forward

India's example underscores the viability of shifting away from DDT while maintaining effective vector control. The GEF-UNIDO project, centered around innovation, partnership, and sustainability, offers a concrete example for other malaria-endemic countries aiming to comply with the Stockholm Convention.

With continued global cooperation and political will, the world can move closer to a future where public health goals are met without compromising environmental and human well-being.

For further information or technical inquiries

Policymakers or technical teams interested in learning more about India’s experience or seeking collaboration under similar initiatives are encouraged to reach out to:

- Dr. Ramdev Yash Pal, National Technical Advisor, UNIDO – y.ramdev [at] unido.org (y[dot]ramdev[at]unido[dot]org)

- Ms. Maren Mellendorf, Project Officer, UNIDO m.mellendorf [at] unido.org (m[dot]mellendorf[at]unido[dot]org)

- Mr. Kuldeep Singh, Chairman and Managing Director at Hindustan Insecticides Limited (HIL) – cmd [at] hil.gov.in (cmd[at]hil[dot]gov[dot]in)

|

Dr. Ramdev Yash Pal, National Technical Advisor, UNIDO

|

|

Ms. Anastasiya Buchok, Senior Project Associate, GGKP |